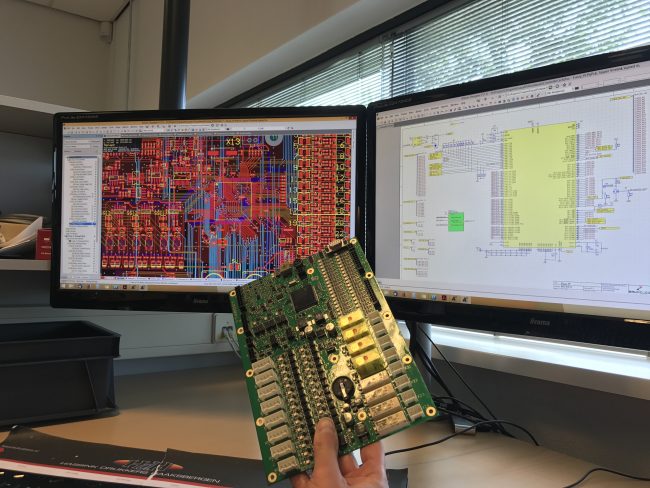

Embedded hardware development

Brunelco can develop a complete embedded solution for you. Think of a solution consisting of both the analogue and digital hardware, programmable logic and the software that determines what the microcontroller does. Of course we can also only carry out a part of your project for you, depending on your wishes and project approach.

Brunelco develops customer-specific electronics. Hardware that can be fully integrated into your product or machine. This hardware is fully optimized for your application, so that all necessary signals can be connected directly to the PCB.

Advantages of own electronics development:

- More compact design

- design adapted to your application

- less installation time

- Reduced risk of wiring errors

- all in one solution

- product protection

- optimal energy consumption

- solution optimized for your operating conditions

- You only need to keep 1 component in stock

- guaranteed delivery over many years

- service-friendly

- customer retention

In order to ensure that you have the right solution in your hands, we go through a development process with a number of fixed components:

First of all, the complete specifications are drawn up. Think of determining the functional requirements, environmental conditions, conditions of use, signal levels and other technically relevant information. In the same phase, we also look at economic aspects: series size, desired cost price, economic lifespan, etc., but also legal regulations, which standards apply, and in which countries the product is used.

After determining the specifications, the system is designed, taking into account of course the testing possibilities (quality assurance), cost price, deliverability of components, producibility and service aspects. The electronic design must fit in well with the software to be developed and must also fit in with the philosophy of the product. This can only be achieved by integral development, so that all aspects are taken into account in the design.

When the system design is ready, an electronic design is made (electrical diagram) and usually the software development starts at the same time. As soon as the electrical scheme is fully implemented, all forms of components are known and the shape of the PCB is known, the print design is made. A prototype is then made of the PCB and fitted with components.

Once the software is ready, the test phase can begin. We check whether the design meets the requirements on all aspects. This is followed by certification (CE) and the product can be taken into production.